- Home

- About Us

- Absorption Process

- Applications

- Publications, Technical Papers, News Releases

- Patent Estate

- Case Studies

- Energy Links

- Contact Us

(410) 266-6521

Get Our News

Sign up below to subscribe to our news

ThermoCharger

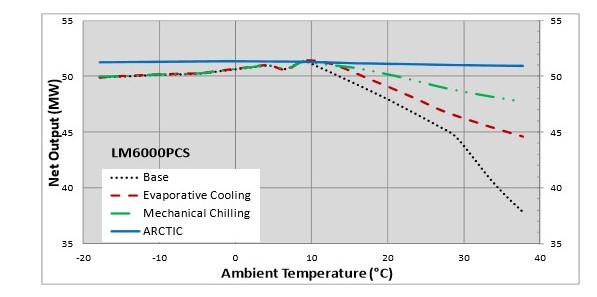

Combustion turbines lose efficiency and power, as inlet air temperature increases. This means that on hot days, turbine power output is significantly decreased from rating conditions (ISO-59°F). Chilling the inlet air with exhaust heat powered refrigeration keeps the turbine output at full rated power, at all ambient conditions. THERMOCHARGER delivers turbine inlet air chilling with no capacity penalty compared to using electric powered refrigeration. Unlike evaporative inlet air cooling (misting) the Thermocharger performance is not humidity dependant and can achieve lower inlet air temperatures. During cold days, the same Thermocharger can be used to provide anti-icing.

Get full rated combustion turbine power throughout the year with THERMOCHARGER.

Typical applications include-

- Power Plants, Micro-Grids, District Chilling, Distributed Generation

- Industrial Cogeneration

- Bio-Digester/ Landfill

- Natural Gas Pipeline Compression

Key Features

System Layout

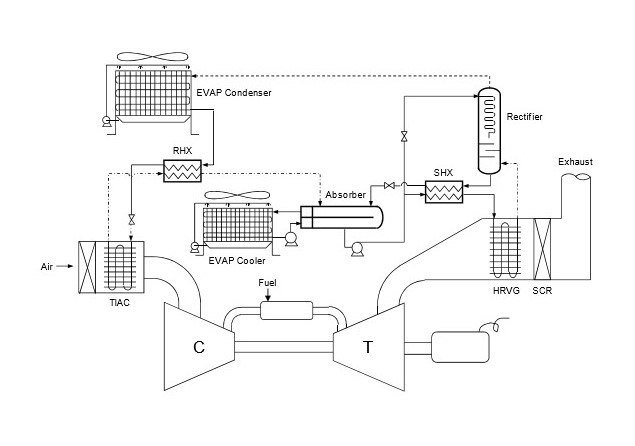

TIAC System Diagram The turbine exhaust warms an aqueous ammonia solution in heat exchanger coils (HRVG) located within the exhaust gas path. The ammonia is then separated in the rectifier to produce a nearly pure refrigerant vapor, which is condensed, reduced in pressure, and then allowed to expand, producing chilling in the turbine inlet air cooling coils (TIAC) located in the inlet air stream. The refrigerant vapor from the cooling coils is reabsorbed by the aqueous ammonia bottoms product from the rectifier (an exothermic process that requires cooling), and is re-pressurized for return to the HRVG. Thus, the process is a closed loop. InstallationsTurbine Inlet Air Chilling at Power Plant

A 2,000-Ton ThermoCharger/ARCTIC installed on a 50 MW gas turbine generator.

A 600-Ton ThermoCharger installed on a Solar MARS 100 gas turbine.

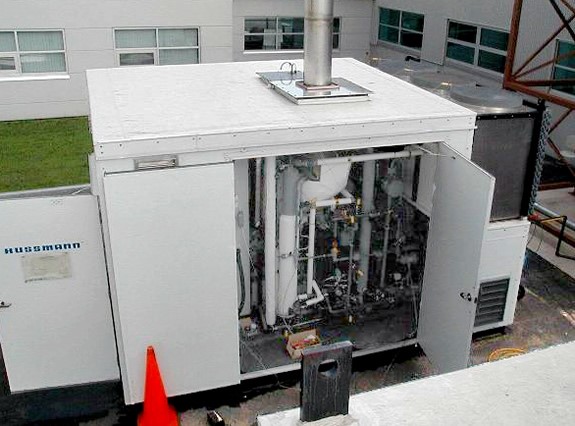

Developed with U. S. Department of Energy, Office of Power Technologies’ Packaged Building Cooling, Heating and Power (BCHP) funding and in partnership with Ingersoll-Rand Energy Systems Advanced Mechanical Technology, Inc. This BCHP system integrates on-site power generation, thermal recovery and thermally activated cooling technologies to provide overall resource efficiency levels of 70% or greater.

20 RT ThermoCharger for BCHP

© Copyright 2000 - 2016 Energy Concepts Co. LLC. All Rights Reserved. |